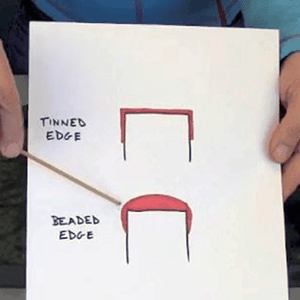

Hi I’m just writing a long list of glass supplies which I need and have noticed that half rounded stained glass lead is approximately £1 per 2m more expensive than flat lead. I have never seen any flat lead – has anyone out there used it? Is it more difficult to use than half rounded, perhaps it marks more easily, or something like that? Does it appear more modern and therefore less authentic? I would really appreciate your help. Rosemary

Milly’s reply: Thanks for your question Rosemary. I’ve used both rounded and flat lead. It depends what you’re doing, and how intricate your design is.

Rounded lead is far better at going around corners, and you’re right – it does look more authentic if you’re restoring or want something to look older.

Flat lead, on the other hand, is perfectly fine, especially if you’re using the thinner widths – you won’t have any problem negotiating bends.

Have a look at: Stained Glass Lead for more information.

Happy bending round corners!

What Width Stained Glass Lead To Use?

Hi, when edging a stained glass panel to go in a door or window frame, what size should the edge lead be? I realise it needs to be wider to allow for the frame rebate, but what is the traditional came used? Also is it an H section or U section that is used? Thank you.

Milly’s reply: Traditionally 12mm lead is used for the edge, as it gives you more strength and more flexibility in terms of adjusting the size. Definitely use the H section – the outsize cames can be trimmed or folded to fit – something you can’t get with the U section.

Have a look at: Stained Glass Lead for more information about different leads.

Happy leading!

Window Question

I am making a window for sidelite next to a front door. It is 8″ x 80″. I plan on leading it, as I think it is the strongest method for this size of window. Would I have to reinforce it in any way? It will be put over an existing window and trimmed into place.

Thanks for your comments.

Milly’s reply:

Thanks for your question Linda, it’s an important issue. As you suggest, the window is narrow enough to not need much support. I’d use a 15mm bead or quarter round around the perimeter to give it more support.

You could always incorporate reinforced lead came or ReStrip across the width in a couple of places to make doubly sure.

That should make it strong enough so that it doesn’t sag. Hope that helps.